Over the years, diamond tools have completely changed the landscape of the stone cutting industry and continue to offer numerous benefits above cutting techniques. This article highlights the advantages of working with diamond tools, which include improved accuracy, durability as well as efficiency and making them suitable and preferred by the professionals. Diamond Tool, because of their unique qualities, are capable of cutting through anything from granite to marble with clean edges and little waste. Besides, fewer frequent tool replacement requirements bring down costs for the companies, which in turn enables them to maintain quality and productivity.

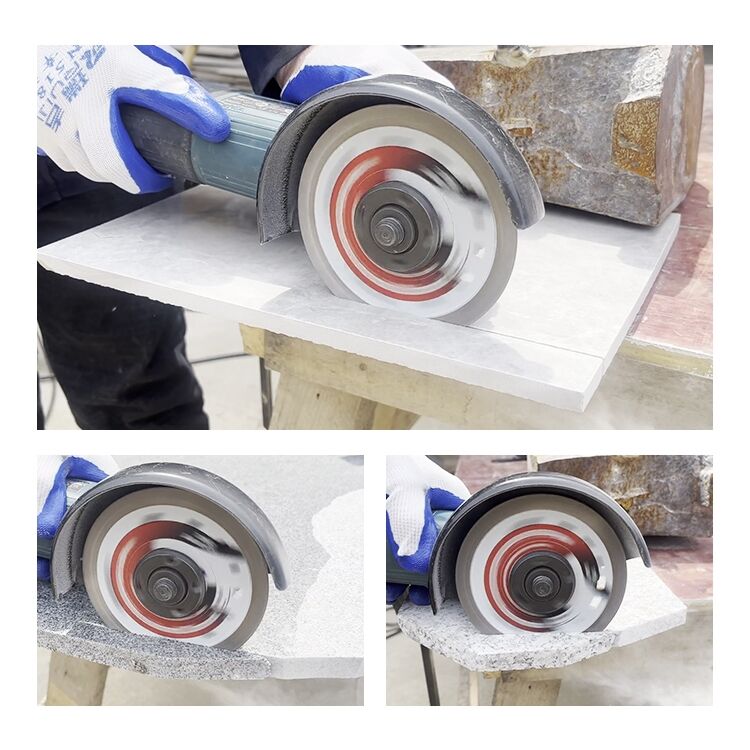

Among the most notable features of diamond tools is their unsurpassed cutting accuracy. The potent properties of the diamond enable to make accurate and clean cuts, which are required at the stone manufacturing. This accuracy not only improves the visual quality but also lowers the quantity of material that is wasted during the operation. In effect, companies are able to utilize their resources more effectively whilst reducing costs, which in turn optimizes earnings.

There’s another important benefit of diamond tools which is the fact that they are very long lasting. Unlike the typical steel blades, diamond blades are able to endure the harshness of stone cutting without sieving to bluntness too soon. This length of time means diamond tools can be used in a great number of projects reducing the downtime that is associated with changing and maintenance of the tools. In addition, the ability to easily cut through tough materials means that projects are completed smoothly and within the set timelines.

In diamond tools a very key factor is efficiency which is the case in most stone cutting operations. The rate of using diamond blades to cut stone is quite impressive hence a project is able to take less time than usual to be completed. This efficiency in time usage not only is a plus to the contractors but also aids in client satisfaction as customers tend to appreciate on-time deliveries and working results of a tight schedule. In a world where quality work in the construction and renovation industry is appreciated, deliverables in a short period become necessary thus increasing the need for diamond tools.

Beyond these practical advantages, the use of diamond cutting tools is also likely to enhance working conditions. Diamond blades provide precise cutting which reduces the risk of injury associated with using other cutting techniques. The use of diamond cutting tools also translates into reduction of vibration and noise and this makes the workspace more habitable to the operators.

As far as stone cutting is concerned, the penetration rate of diamond tools is only going to increase. New development in diamond technology will pave way for many more cutting systems which will be faster and better than the existing ones. Industry professionals are beginning to appreciate the economics of purchasing top class diamond tools which enable them to be more competitive in terms of quality, productivity, safety and even efficiency. It is almost obvious that as long as the current development trend continues, diamond tools will stay as the cutting edge of stone cutting technologies for decades.