Every industry, whether it be construction or the detailing of cars, requires precise surface finishing and polishing. Professional diamond polishing pads stand out as the pad of choice for achieving such results. The article below explains all the best practices needed to properly utilize diamond polishing pads.

What Are Diamond Polishing Pads?

Diamond polishing pads are made out of diamond making them much more durable and efficient than traditional alternatives. These pads can be used on multiple surfaces such as granite, marble and stone. Depending on the type of diamond polishing pad selected, one can achieve different levels of shine and smoothness ranging from rough to perfect polish. Understanding the primary characteristics of each pad and its corresponding finish will allow perfection.

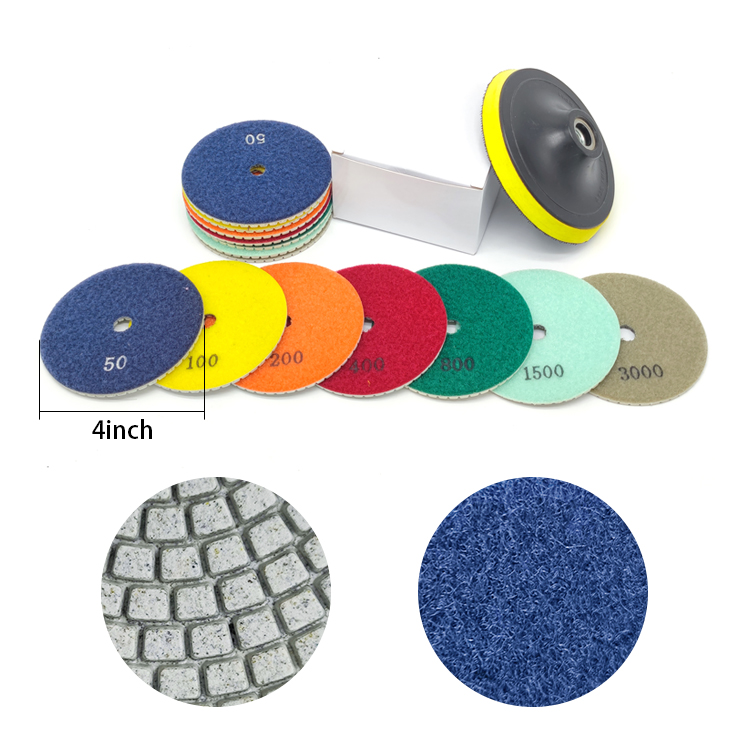

Selecting the Best Grit For The Job

Selecting the right grit for the pad can greatly enhance the type of finish achieved for any given project. Diamond polishing pads with a coarse grit level between 50-200 are optimal for body shaping and preparing surfaces for medium grit pads. Medium grit pads having an 400-800 level index are best for honing down already prepped surfaces. Diamond pads with shiny gleam grades of 1500 to 3000 are the go-to choice for proficiently polishing and achieving gloss finishes.

Ways of Polishing a Surface

If the final results are to look great, the right techniques should be employed along with the use of diamond polishing pads. Start with ensuring the surface is ready by removing any dust. With a variable speed polisher, control the speed and the pressure of the pad used. It is advisable to work in small sections, applying constant pressure and removing the pad overlapping each pass to avoid missing certain spots. Furthermore, applying water or a polishing compound will increase the effectiveness of the pads while minimizing dust.

How to take Care of Diamond Polishing Pads

Taking care of the diamond polishing pads ensures they perform well and also makes them last longer. Firstly, after use make sure to rinse the pads to remove all residue. Let them dry off fully before placing them in a cool dry space. Secondly, constantly looking for signs of wear and tear ensures that the pads are appropriately replaced, thus always having the best tools for the job.

Industry Trends and Innovations

The progression of NASA’s technological advancements had laid the groundwork of the diamond polishing pad industry and made it evolve. Innovations have been made relatively recently by the creation of pads that are eco-friendly and reduces impact to the environment but still performs very well. Furthermore, producers are making pads that are more flexible and adaptable which allows them to work on a variety of surfaces. Keeping up with these trends will aid professionals determine what product works best for them while ensuring that they remain successful within their field.

In conclusion, the diamond polishing pad is a very versatile tool that can be used in a wide range of applications and so making use of it appropriately will help people achieve the perfect finish. Understanding the types, having the right skills, and knowing the industry will guarantees full satisfaction to consumers and professionals alike.