ድንጋይ ወይም ኮንክሪት በሚያብሩበት ጊዜ ተስማሚ የሆነ የአልማዝ ማጣሪያ መምረጥ ውጤቱን ለመወሰን ትልቅ ሚና ይጫወታል። በገበያው ላይ ምርጫዎች አሉ፣ ነገር ግን ውሳኔውን በሚያደርጉበት ጊዜ ወሳኝ የሆኑትን ነገሮች ማወቅ በተከናወነው ሥራ ጥራት ላይ ከፍተኛ ተጽዕኖ ሊያሳድር ይችላል። በዚህ ርዕስ ውስጥ፣ እንደ ፓድ ዓይነት፣ የሸክላ መጠን እና የተወሰኑ ፓድዎችን መጠቀም ያሉ አስፈላጊ የሆኑ አንዳንድ ነገሮችን እንመለከታለን፣ ይህም የሚያስፈልግህን ተስማሚ የፖሊሽ ፓድ ለማግኘት ነው።

የመረጡት መስፈርት የመጀመሪያው እርምጃ የአልማዝ ማጣሪያ ፓድ የሚጠቀሙበትን ቁሳቁስ ማወቅ ነው; እንደ ግራናይት ፣ ኳርትዝ ፣ ኮንክሪት ወይም እብነ በረድ ። የተለያዩ ቁሳቁሶች በተፈጥሮ የተለያዩ ልዩ ልዩ የተሰሩ ፓድዎችን ይጠይቃሉ። ለምሳሌ ያህል፣ በእንጨት ላይ የተሠራው የማርበር ማጣሪያ ቁሳቁስ ለስላሳ መሆን አለበት፤ የግሪኒት ማጣሪያ ግሪድ ደግሞ በግሪኒት ባህሪ ምክንያት ጠንካራ መሆን አለበት። ስለዚህ ምን ዓይነት ቁሳቁስ እንደሚፈልጉ ማወቅህ ብዙ ምርጫዎችን ለማስወገድ ይረዳሃል፤ እንዲሁም ጥሩ ውጤት ያስገኛል።

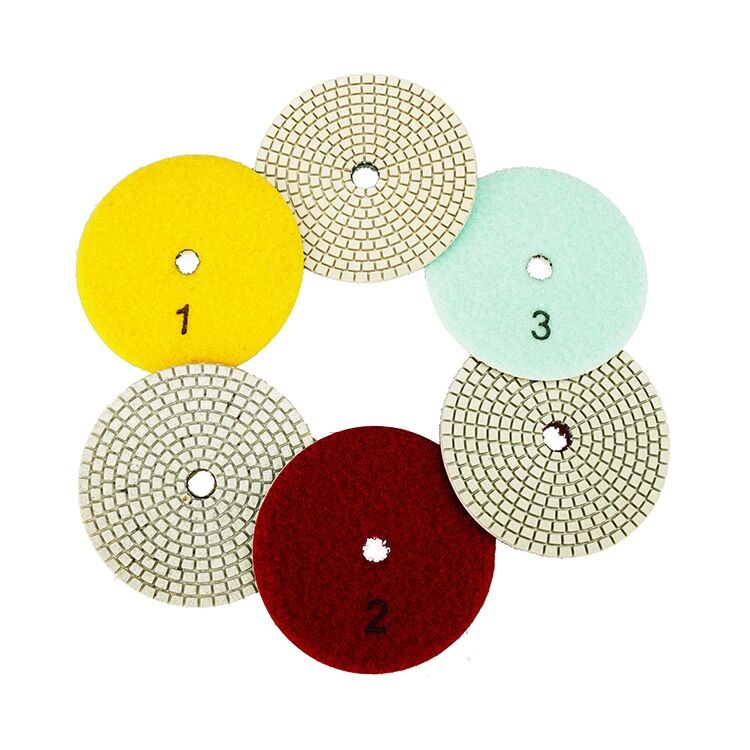

የአልማዝ ማጣሪያውን ጥራዝ መጀመሪያ ላይ የተሠራው ቁራጭ ከ30 እስከ 50 የሚደርስ አካባቢ ላይ ለማከናወን ከጠባብ ወለል ጋር መሄድ ነው። ይህ ሂደት ሲካሄድና ትንሽ ሻካራ የሆነ ገጽታ ሲያጋጥምህ፣ ያልተስተካከለውን ነገር ለማስተካከል ጥቃቅን የሆነ ድንጋይ የሚገጣጠም ፓድ ያስፈልጋል። ይሁን እንጂ መካከለኛ ወይም ጥሩ በሆነ ማጥፊያ መሳሪያ መሥራት ከፈለጋችሁ ከዚያ በኋላ 100 ወይም 200 የሸክላ መደርደሪያዎችን መጠቀም ትችላላችሁ። የሸክላ መጠን እንዴት እንደሚሰራ መረዳት ለትክክለኛ ማጣራት ወሳኝ ነው።

የተጨማሪው ነገር፣ የጎንታት ምATERIAL አንዱ ይህን ተመለስ። ዲያምንድ የተነሣ ጎንታት velcro፣ resin እና metal-backed ናቸው። velcro backing አሁን የሚፈልግበት ነው ትክክለኛ ነው ስለዚህ ጎንታት በአንድ ሰከንድ መካከል እንደሚቀጥላሉ ነው እና የተደረገው የአንዳንድ ደረጃ ያለው ነው የተደረገው የተደረገው ነው የተደረገው ነው እና የተደረገው ነው እና የተደረገው ነው እና የተደረገው ነው እና የተደረገው ነው እና የተደረገው ነው እና የተደረገው ነው።

በተጨማሪም የአልማዝ ማጣሪያውን ዓላማ ልብ በል። የቤት ውስጥ ሥራዎች ለምሳሌ፣ የሸክላውን ገጽታ ለማሻሻል የሸክላ ማጣሪያ ይጠቀማሉ፤ የሸክላውን ገጽታ ለማጣራት ደግሞ የሸክላ ማጣሪያ ይጠቀማሉ። ይህ ለድርጅቱ የሚመከረው ቦታ ለመወሰን ይረዳዎታል።

ለመጨረሻ ጊዜ ለመጥቀስ ያህል ትክክለኛውን የአልማዝ ማጣሪያ ፓድ ምርጫ አንድ ሰው የቁሳቁስ ዓይነቶችን ፣ የሸክላ ደረጃዎችን ፣ የድጋፍ አማራጮችን እና በመጨረሻም የፓዱን አተገባበር እንዴት እንደሚተረጉም ይወሰናል ። እነዚህን ነገሮች መመርመር ትክክለኛ ውሳኔዎች ከፖሊሽ ግቦች ጋር የሚስማሙ መሆናቸውን ያረጋግጣል ። በቅርብ ጊዜ ውስጥ ኢንዱስትሪው እየተለወጠ ሲሄድ አዲስ ቴክኖሎጂ ይጠበቃል ፣ ይህም የአልማዝ ፓዶችን በተሻለ እና በፍጥነት የማጣራት ሥራዎችን እንዲያከናውኑ የሚያስችላቸውን እድገቶች ያመጣል ። ፕሮጀክቶችህን በተሻለ መንገድ ለመሥራት እንድትችል የቅርብ ጊዜዎቹን እድገቶች መከታተልህን አስታውስ።