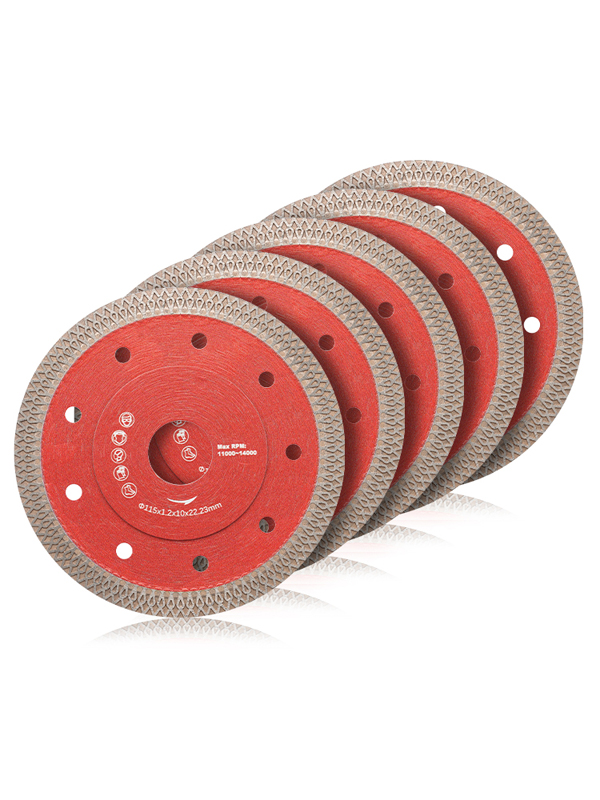

Introducing: the vacuum brazed diamond saw blade. These blades are some of the highest performing and longest lasting tools in the cutting industry as they eliminate the weaknesses presented by conventional saw blades. With the help of specialized vacuum brazing, the blades provide a higher level of durability and efficiency. The following article will examine some of the benefits of vacuum brazed diamond saw blades including their applications and benefits for both professionals and domestic users.

The first advantage of vacuum braided diamond blades is the cutting performance of the tool of such a mechanism. The diamond particles are not let loose from the blade and therefore, many materials such as concrete, stone and ceramics can be cut much faster and much more smoothly. This time efficiency also reduces the amount of wear and tear caused on the blade itself and therefore its lifespan is extended. For contractors and construction professionals, this means less blade changes and downtime overall productivity goes up on the job site.

Something that is also very revolutionary is the cross functionality of the vacuum brazed diamond saw blades. They can be used for a variety of uses such as cutting, grinding and drilling. Be it a mega construction project or a simple home improvement, these blades assist in many types of materials and works. Such flexibility also makes it a useful refinishing and surface finishing tools for any professional or a do it yourself enthusiast who needs perfection in every undertakings to achieve the required objectives.

In addition, the vacuum brazed diamond saw blades have very low chipping or cracking which is often the case with the traditional blades. This feature not only improves the quality of the cut but it also ensures safety of the users at the time of the cut. The users can work without much fear as these blades offer a good cutting experience that is dependable and helps to minimize the chances of accidents that result from blade failure.

Moreover, in terms of production process, vacuum brazed diamond saw blades are manufactured in environmentally safer way than others. In the vacuum brazing method, energy and waste are minimized because this technique does not require excessive layers making it ideal for those seeking an eco-friendly process. The construction industry has been adopting greener goals over the last few years and for companies that want to comply with green standards, eco friendly solutions such as the vacuum brazed diamond saw blades are important.

To sum it up, there is a growth in the vacuum brazed diamond saw blades market thanks to the high-performance cutting tools demand. With that in mind, manufacturers keep improving the quality and performance of these blades so that they do not fade in competition. For people who wish to incorporate the newest and the most advanced technology in their work, knowledge of such trends is very important.

To wrap things up, vacuum brazed diamond saw blades have you covered if you are a modern-day user. These blades have superior cutting performance, multipurpose characteristics, high durability, low eco impact, and thus are destined to become the power tools of choice for both the pros and the novices. With such a growth of the industry, it will be necessary for the people who to stay relevant to the industry to adopt such technologically advanced instruments.